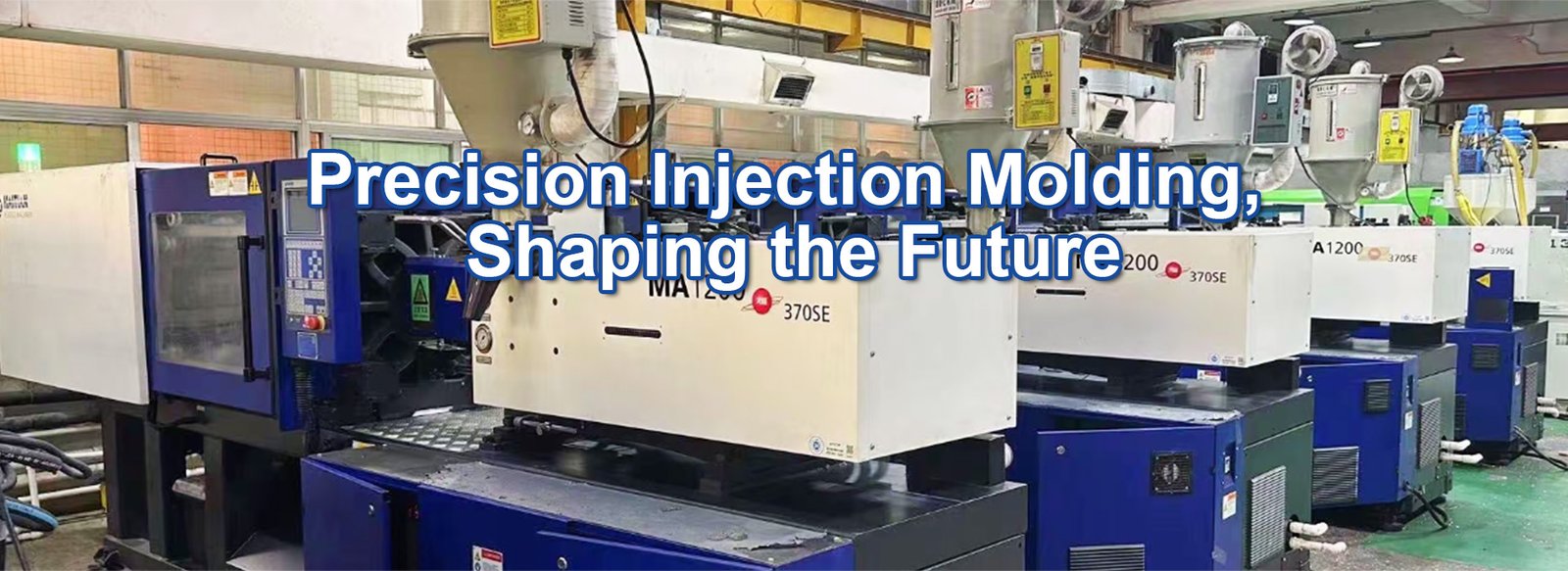

Professional partner in injection molding design in China!

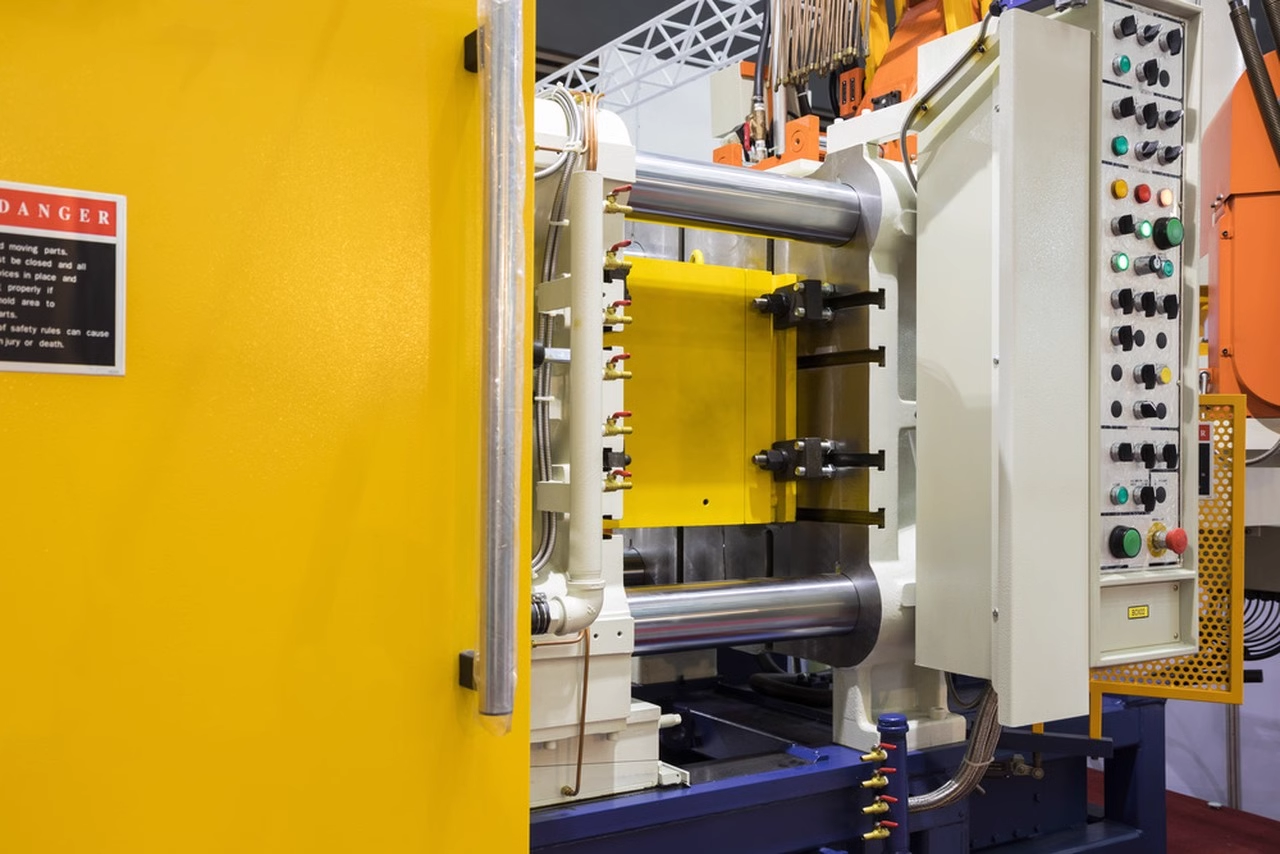

Plastic injection molding technology is one of the most common methods for producing plastic products Hangzhou Xinxing Electronics focuses on large-scale plastic injection molding production, utilizing advanced machinery to achieve the best results. Given the high energy costs in Europe, Chinese manufacturing provides more cost-effective solutions.

Hangzhou Xinxing Electronics produces high-quality plastic components for various industries and provides comprehensive post production services. To meet the specific needs of the industry, Hangzhou Xinxing Electronics provides ISO8 cleanroom production for the injection molding field. TDL is committed to strict quality control and uses stainless steel to manufacture molds according to SPI-SPE standards. These sturdy molds are compatible with various materials and are used to manufacture various products.

Our plastic accommodation craft

The process of injection molding not only involves the above physical operation, also includes the selection of plastic materials, mold design and manufacturing, and injection molding machine parameter setting and other aspects of comprehensive consideration, to ensure the quality of the final product and production efficiency

Closing

This is the beginning of the forming process, the mold is tightly closed, ready for the injection of plastic.

Injection

This is the beginning of the forming process, the mold is tightly closed, ready for the injection of plastic.

Pressure holding

This is the beginning of the forming process, the mold is tightly closed, ready for the injection of plastic.

Cooling

This is the beginning of the forming process, the mold is tightly closed, ready for the injection of plastic.

Opening molda

This is the beginning of the forming process, the mold is tightly closed, ready for the injection of plastic.

Product removal

This is the beginning of the forming process, the mold is tightly closed, ready for the injection of plastic.

Our technological advantages

Selecting the right plastic material in injection molding is the key to ensuring product quality and performance. When choosing plastic materials, it is necessary to consider many factors such as the functional requirements of the product, environmental conditions, cost and processing performance. Understanding the characteristics of different plastic materials, considering the functional requirements and environmental conditions of the product, evaluating costs and processing properties, and referring to existing successful cases and experience are important steps in selecting the right plastic materials.

At the same time, communication and cooperation with professional injection molding manufacturers can obtain more professional material selection advice and support. Only through the scientific and reasonable selection of plastic materials can we ensure that the product has good quality and performance in the injection molding process.

Selecting the right plastic material in injection molding is the key to ensuring product quality and performance. When choosing plastic materials, it is necessary to consider many factors such as the functional requirements of the product, environmental conditions, cost and processing performance. Understanding the characteristics of different plastic materials, considering the functional requirements and environmental conditions of the product, evaluating costs and processing properties, and referring to existing successful cases and experience are important steps in selecting the right plastic materials.

At the same time, communication and cooperation with professional injection molding manufacturers can obtain more professional material selection advice and support. Only through the scientific and reasonable selection of plastic materials can we ensure that the product has good quality and performance in the injection molding process.

Selecting the right plastic material in injection molding is the key to ensuring product quality and performance. When choosing plastic materials, it is necessary to consider many factors such as the functional requirements of the product, environmental conditions, cost and processing performance. Understanding the characteristics of different plastic materials, considering the functional requirements and environmental conditions of the product, evaluating costs and processing properties, and referring to existing successful cases and experience are important steps in selecting the right plastic materials.

At the same time, communication and cooperation with professional injection molding manufacturers can obtain more professional material selection advice and support. Only through the scientific and reasonable selection of plastic materials can we ensure that the product has good quality and performance in the injection molding process.

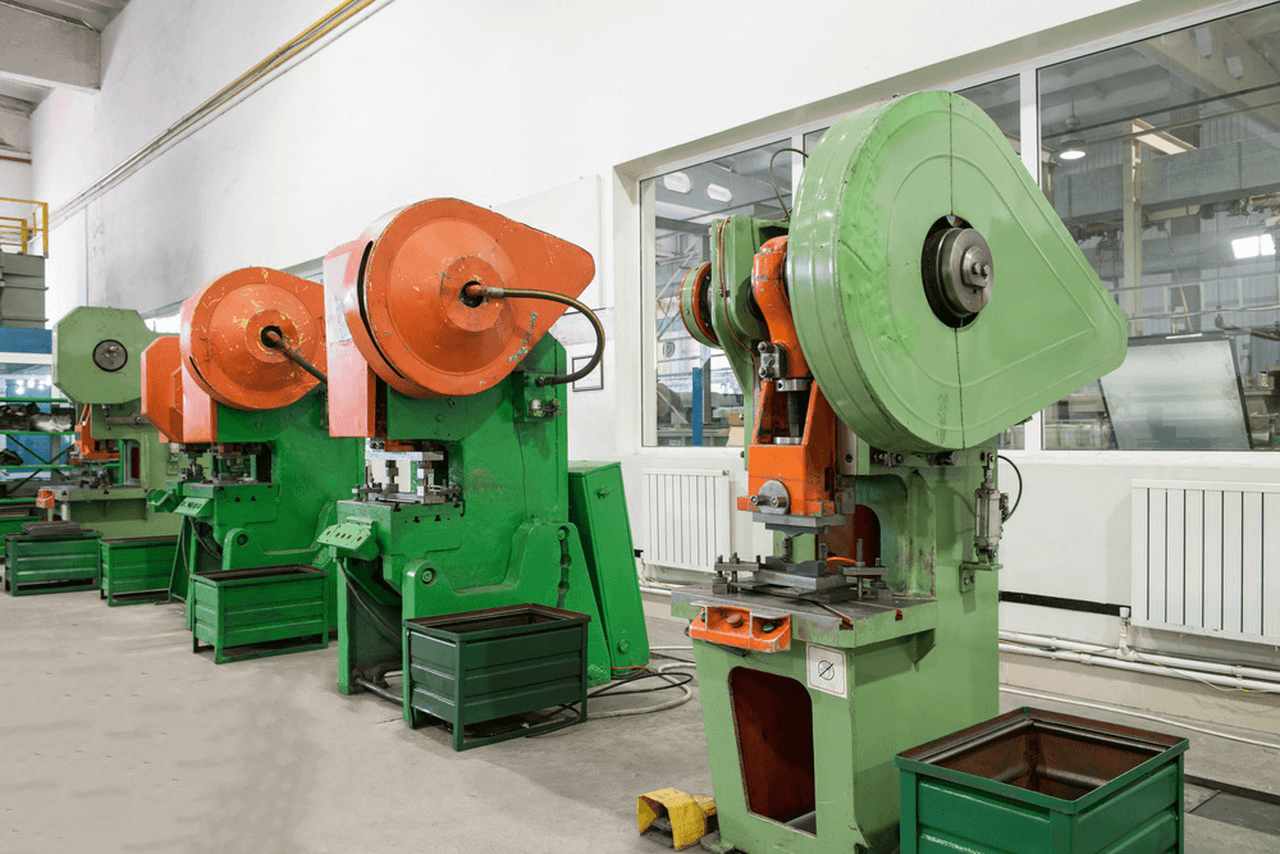

Our equipments

our team

Our craft team

The process technology team focuses on providing efficient technical support and solutions for industrial production. The core members are composed of experienced process technicians, who have profound attainments in the fields of casting, stamping, welding, painting, etc., and can quickly solve production problems. The team also includes young process engineers, who have innovative thinking and solid knowledge to inject vitality into the team. The team is equipped with advanced experimental equipment to ensure the optimization and improvement of the process flow. We are committed to promoting the continuous development and innovation of industrial production.

Our sales team

Our management team

Our after-sales service team

Our craft team

The process technology team focuses on providing efficient technical support and solutions for industrial production. The core members are composed of experienced process technicians, who have profound attainments in the fields of casting, stamping, welding, painting, etc., and can quickly solve production problems. The team also includes young process engineers, who have innovative thinking and solid knowledge to inject vitality into the team. The team is equipped with advanced experimental equipment to ensure the optimization and improvement of the process flow. We are committed to promoting the continuous development and innovation of industrial production.

Our sales team

Our management team

Our after-sales service team

Our craft team

The process technology team focuses on providing efficient technical support and solutions for industrial production. The core members are composed of experienced process technicians, who have profound attainments in the fields of casting, stamping, welding, painting, etc., and can quickly solve production problems. The team also includes young process engineers, who have innovative thinking and solid knowledge to inject vitality into the team. The team is equipped with advanced experimental equipment to ensure the optimization and improvement of the process flow. We are committed to promoting the continuous development and innovation of industrial production.

Our sales team

Our management team

Our after-sales service team

Our craft team

The process technology team focuses on providing efficient technical support and solutions for industrial production. The core members are composed of experienced process technicians, who have profound attainments in the fields of casting, stamping, welding, painting, etc., and can quickly solve production problems. The team also includes young process engineers, who have innovative thinking and solid knowledge to inject vitality into the team. The team is equipped with advanced experimental equipment to ensure the optimization and improvement of the process flow. We are committed to promoting the continuous development and innovation of industrial production.

Our sales team

Our management team

Our after-sales service team

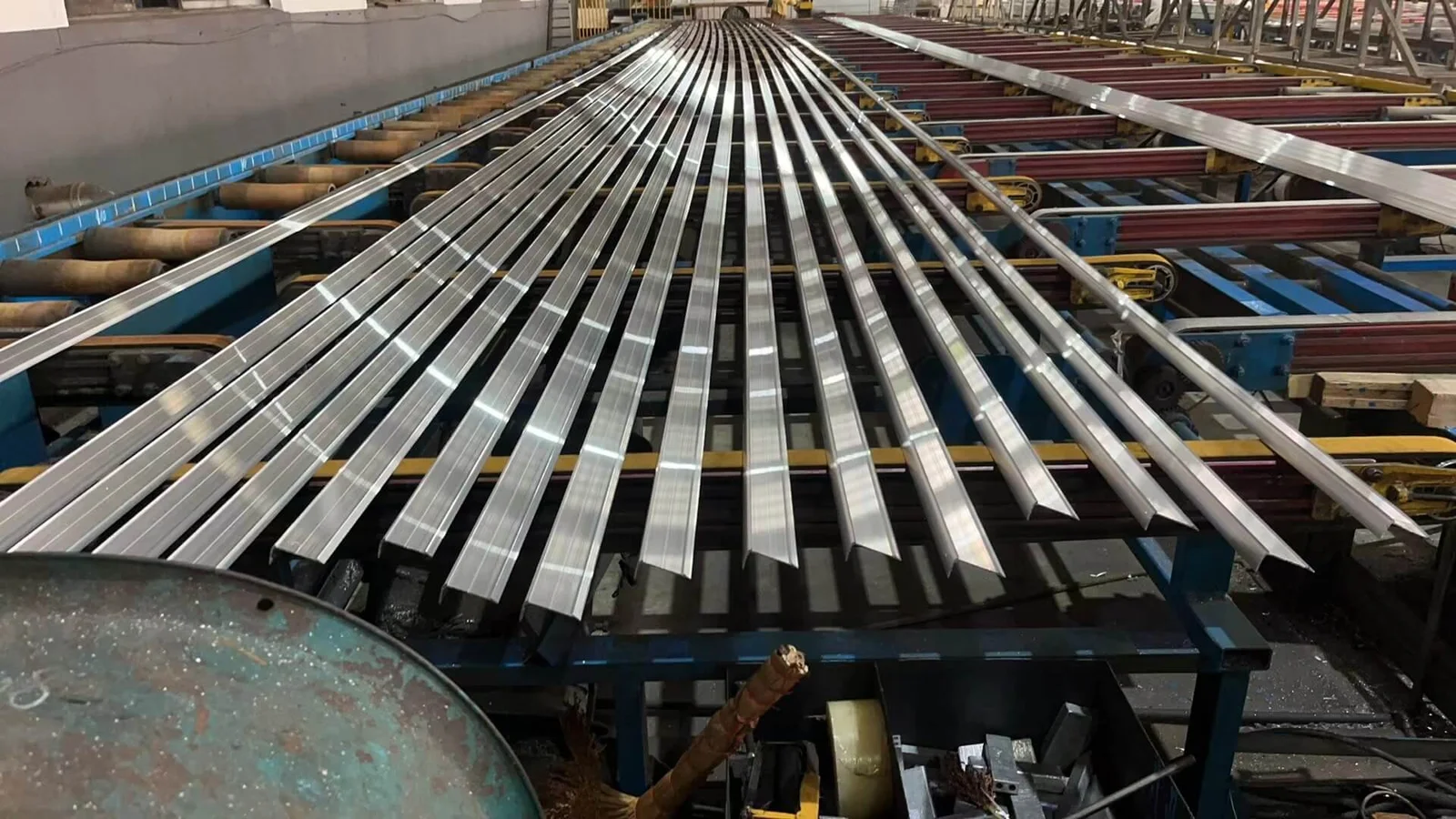

Aluminum Extrusion

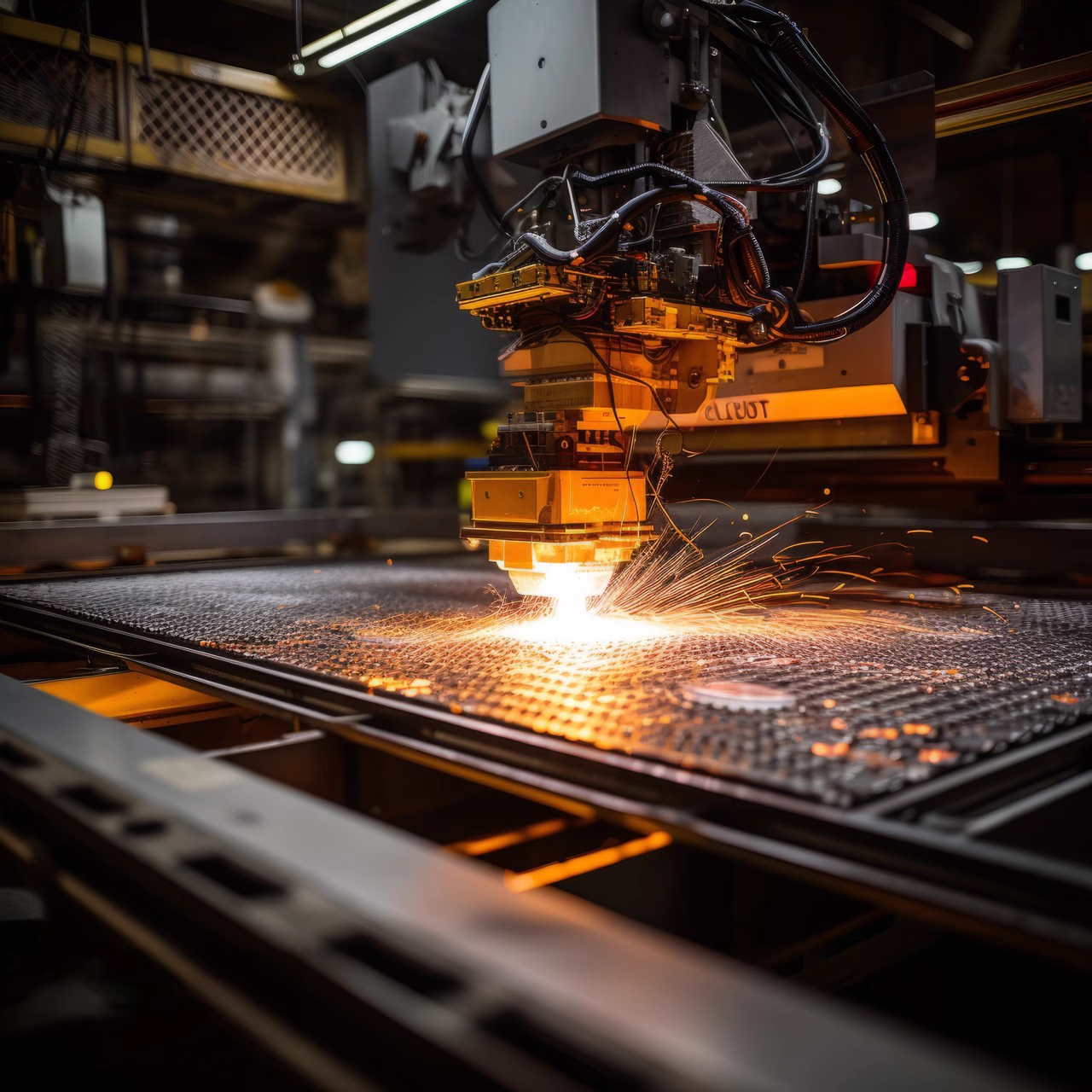

Laser Cutting

Oxidation

CNC Machine Tool Production

Metal Die Casting