Professional partner in injection molding design in China!

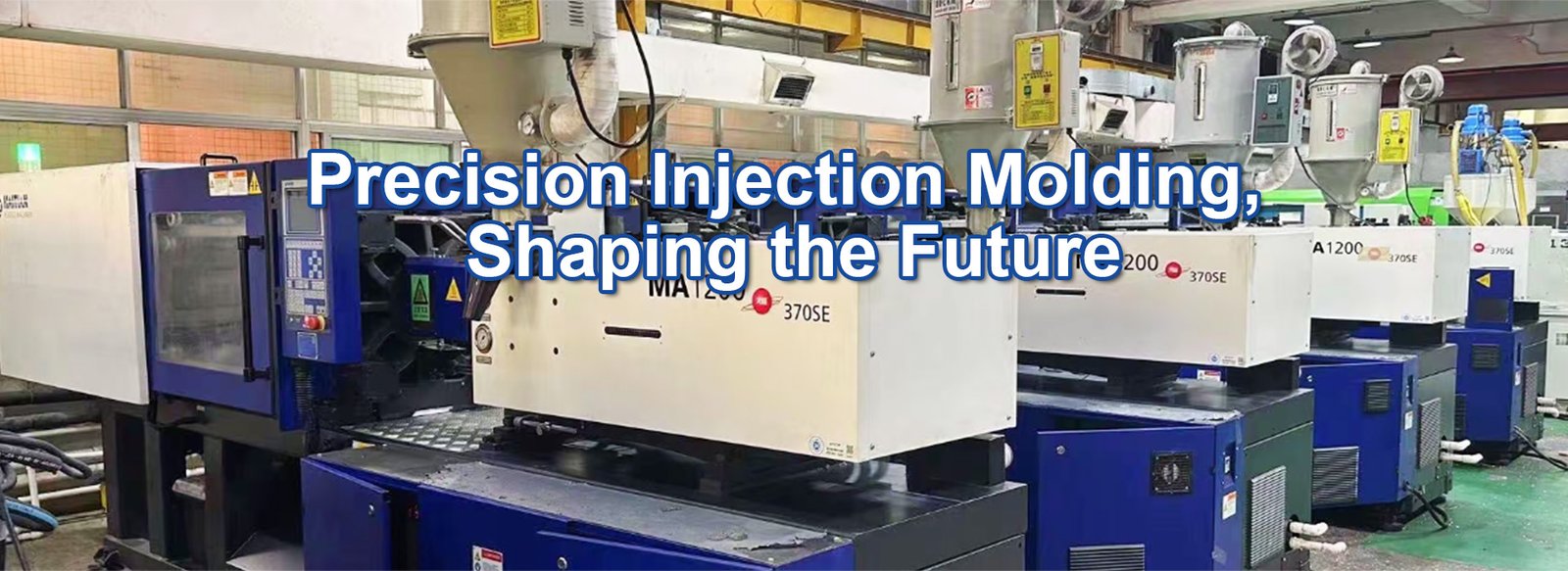

Plastic injection molding technology is one of the most common methods for producing plastic products Hangzhou Xinxing Electronics focuses on large-scale plastic injection molding production, utilizing advanced machinery to achieve the best results. Given the high energy costs in Europe, Chinese manufacturing provides more cost-effective solutions.

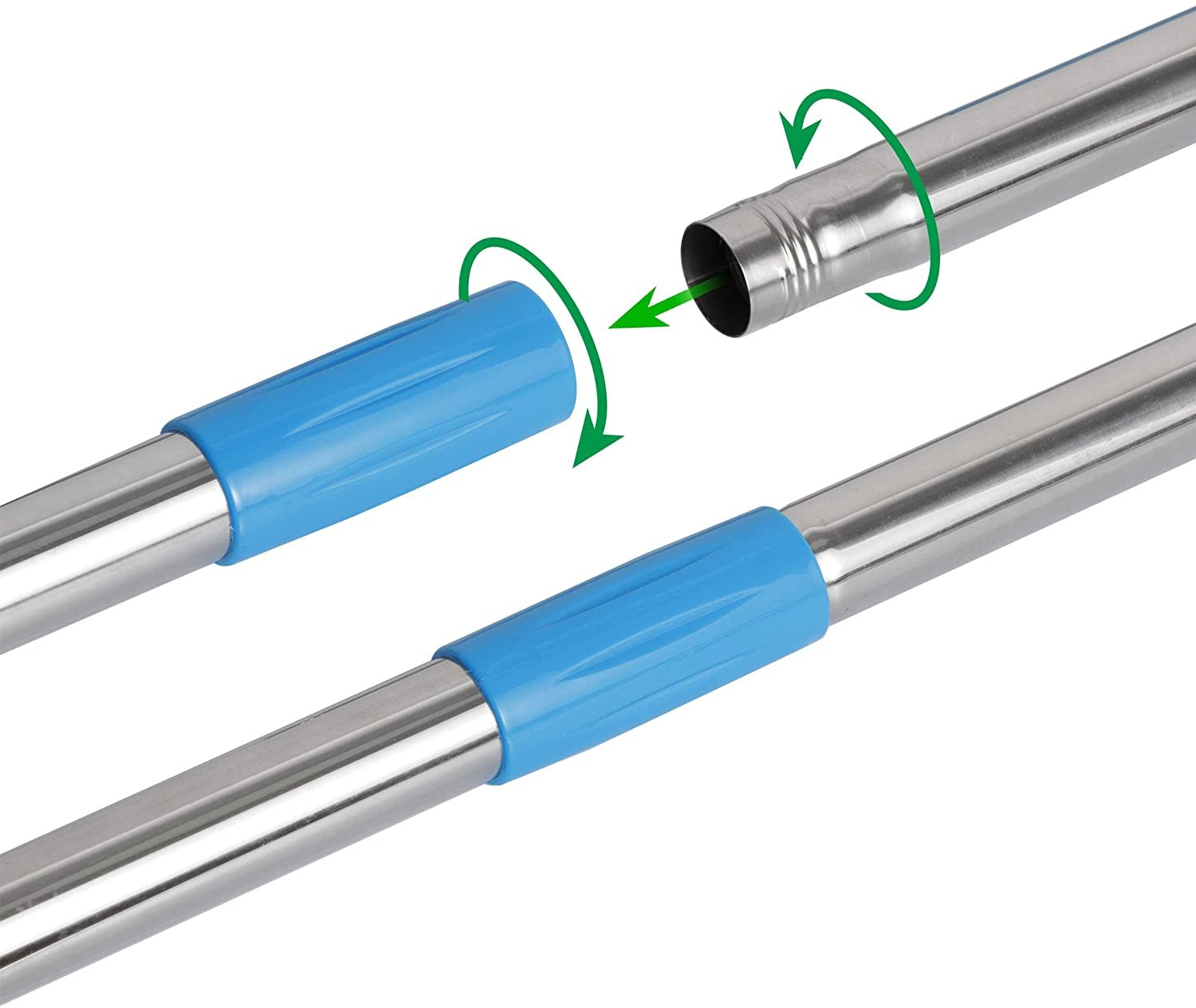

Hangzhou Xinxing Electronics produces high-quality plastic components for various industries and provides comprehensive post production services. To meet the specific needs of the industry, Hangzhou Xinxing Electronics provides ISO8 cleanroom production for the injection molding field. TDL is committed to strict quality control and uses stainless steel to manufacture molds according to SPI-SPE standards. These sturdy molds are compatible with various materials and are used to manufacture various products.

Our plastic accommodation craft

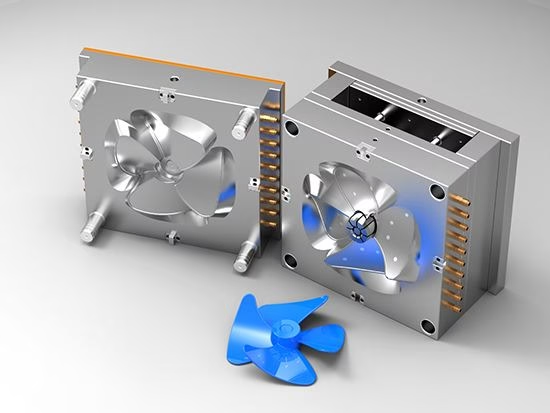

The process of injection molding not only involves the above physical operation, also includes the selection of plastic materials, mold design and manufacturing, and injection molding machine parameter setting and other aspects of comprehensive consideration, to ensure the quality of the final product and production efficiency

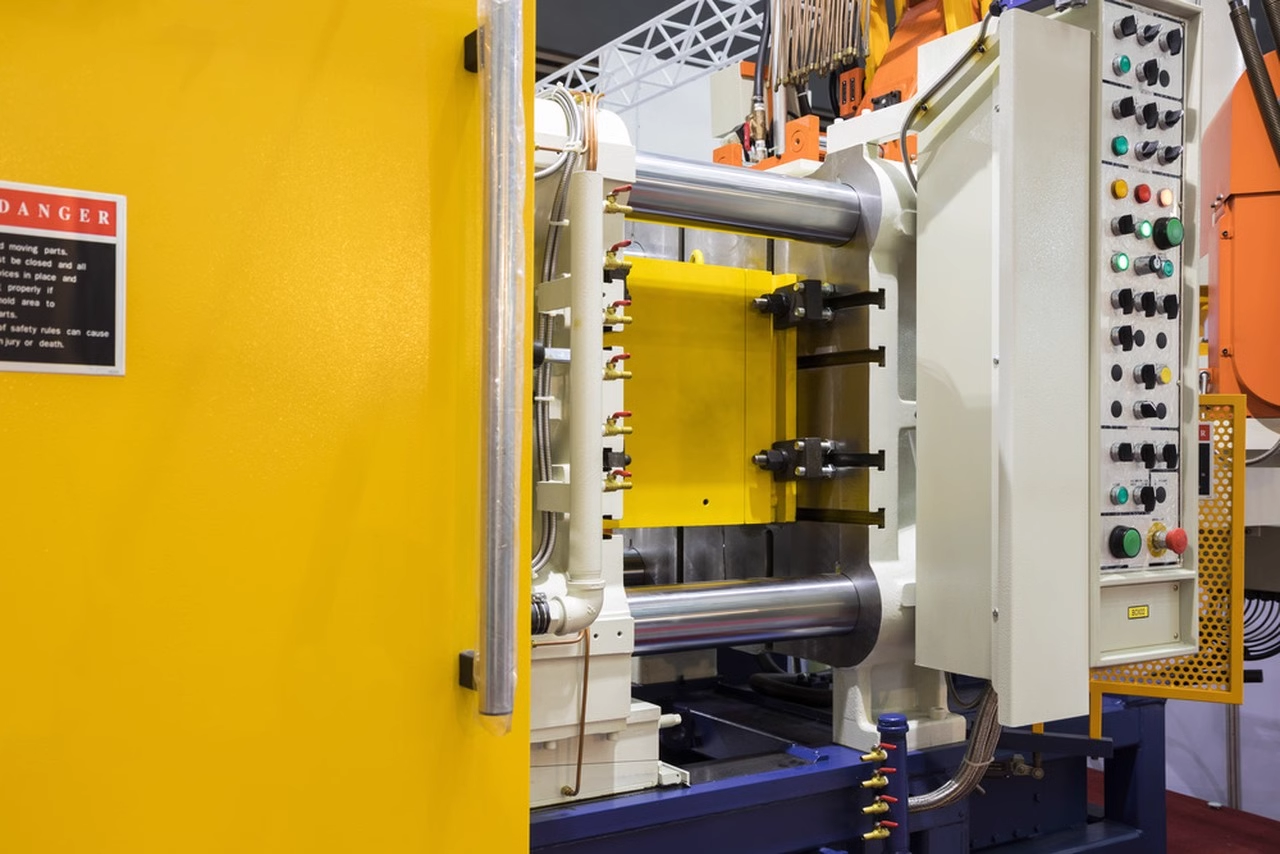

Closing

This is the beginning of the forming process, the mold is tightly closed, ready for the injection of plastic.

Injection

Plastic is heated to a molten state in an injection molding machine, and then injected into the die cavity by high pressure.

Pressure holding

After the plastic is filled in the mold cavity, the injection molding machine maintains a certain pressure to to ensure that the plastic is fully filled in every corner of the mold cavity.

Cooling

Plastic cooling and curing in the mold, this is a very important part of the forming process, because only after cooling and curing to a certain rigidity, release can avoid plastic products due to external force deformation. cooling time accounts for 70% ~ 80% of the whole molding cycle, well designed cooling system can greatly shorten the molding time, improve injection molding productivity, reduce costs.

Opening molda

Plastic products in the mold after cooling and curing, mold is opened, in order to take out the formed plastic products.

Product removal

Molded plastic products are removed from the mold, to complete the whole injection molding process.

The injection molding process also includes the selection of an injection molding machine with a large enough clamping force to prevent mold expansion and effectively maintain pressure. In addition, under the new injection molding environment of , also need to consider some new injection molding processes, such as gas-assisted molding, water-assisted molding, foam injection molding, to improve product quality and production efficiency.

Our technological advantages

Selecting the right plastic material in injection molding is the key to ensuring product quality and performance. When choosing plastic materials, it is necessary to consider many factors such as the functional requirements of the product, environmental conditions, cost and processing performance. Understanding the characteristics of different plastic materials, considering the functional requirements and environmental conditions of the product, evaluating costs and processing properties, and referring to existing successful cases and experience are important steps in selecting the right plastic materials.

At the same time, communication and cooperation with professional injection molding manufacturers can obtain more professional material selection advice and support. Only through the scientific and reasonable selection of plastic materials can we ensure that the product has good quality and performance in the injection molding process.

First, understand the product needs

1. Define the size, shape and accuracy requirements of the product.

2. Consider the use environment and functional requirements of the product.

Second, material selection

1. According to the product characteristics and injection molding process, choose the appropriate mold material.

2. Consider the wear resistance, heat resistance and corrosion resistance of the mold material.

Third, mold structure design

1. Reasonable parting surface design to ensure the smooth process of injection molding.

2. Optimize the pouring system and cooling system to improve production efficiency and product quality.

4. Manufacturing process

1. Inspect the process level and quality control of mold manufacturers.

2. Choose a factory with advanced manufacturing equipment and technology.

V. Cost-benefit analysis

1. On the premise of meeting the demand, compare the price and service life of different molds.

2. Comprehensive consideration of cost and benefit, choose cost-effective mold.

Six, case analysis through the actual case, show how to choose the appropriate injection mold according to the specific situation.

Summarize the key factors and methods for selecting molds suitable for injection molding, and emphasize the importance of comprehensive consideration of various factors.

Ensure the molding quality of plastic products

1.By controlling the mold temperature, the cooling system can ensure that the plastic is cooled and set quickly in the mold, thereby improving the surface quality and dimensional accuracy of the product.

Prolong the service life of the mold

2.Proper cooling can reduce the mold temperature and reduce thermal stress, thus extending the service life of the mold.

Improve production efficiency

3.Rapid cooling can shorten the molding cycle, improve production efficiency and reduce production costs.

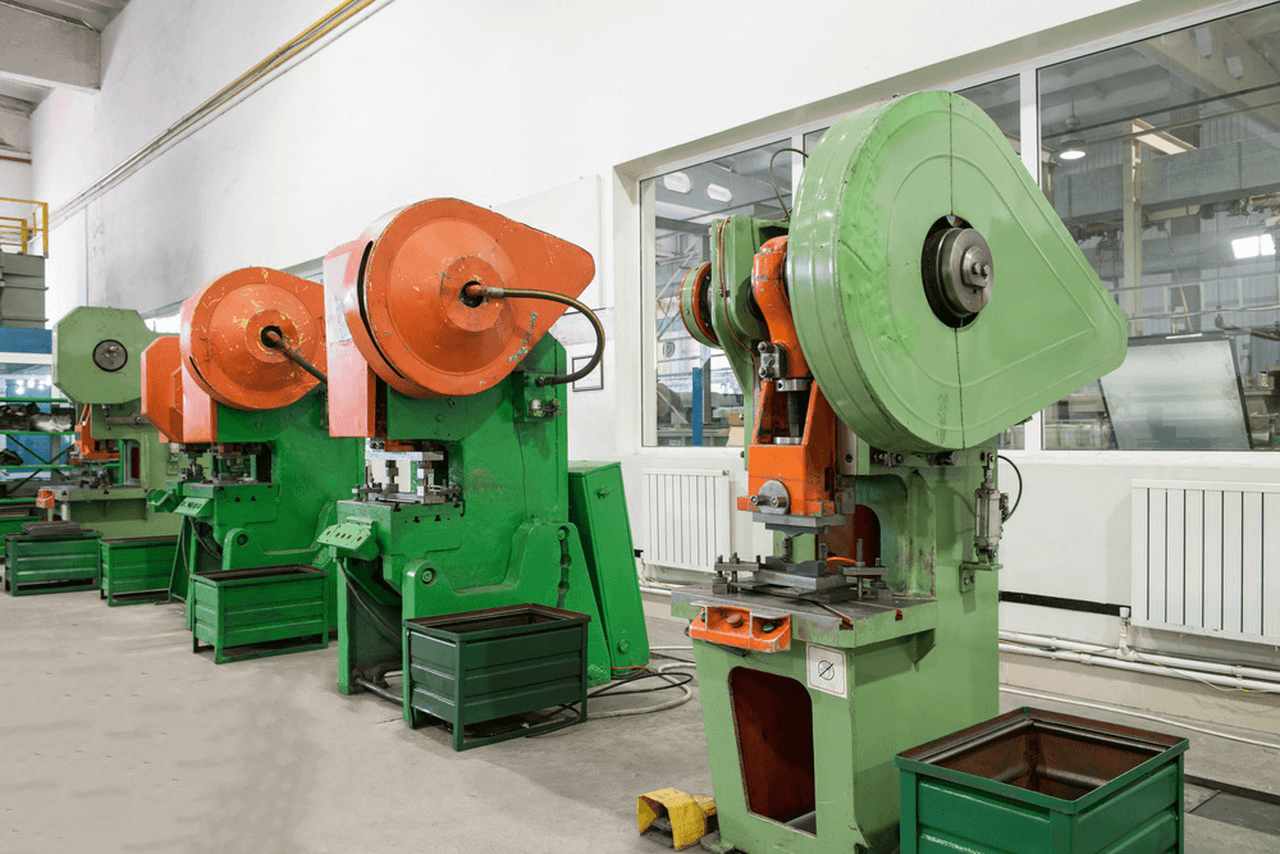

Our equipments

our team

Our craft team

The process technology team focuses on providing efficient technical support and solutions for industrial production. The core members are composed of experienced process technicians, who have profound attainments in the fields of casting, stamping, welding, painting, etc., and can quickly solve production problems. The team also includes young process engineers, who have innovative thinking and solid knowledge to inject vitality into the team. The team is equipped with advanced experimental equipment to ensure the optimization and improvement of the process flow. We are committed to promoting the continuous development and innovation of industrial production.

Our sales team

1. Team members

Our sales team consists of a group of experienced and dynamic members, each with a unique expertise in the field of sales.

2. professional ability

Team members have deep professional knowledge, can accurately grasp customer needs, to provide professional products and services.

3. Sales performance

The team has achieved remarkable sales performance, steadily increased its market share, and won wide recognition from customers.

4. Customer feedback

We value customer feedback, take customer needs as the orientation, and continuously improve service quality and customer satisfaction.

5. Spirit of cooperation

Team members work closely together to meet challenges and ensure successful sales targets.

6. Continuous innovation

The team continues to explore new sales strategies and technical means to maintain a leading position in the market.

Vii. Future Development

In the future, we will continue to strengthen team building, enhance professional capabilities, and provide customers with more excellent services.

Our management team

First, core members

Our management team consists of senior industry experts with extensive management experience and forward-looking strategic vision.

Second, management style

We focus on people-oriented management, encourage teamwork, and work together to address challenges through open and transparent communication.

3. Decision-making ability

With data analysis and market research, we make quick decisions to ensure the company’s steady growth.

Fourth, strategic vision

We have insight into market trends, timely adjustment of strategy, and point out the direction for the development of the company.

5. Social Responsibility

We actively fulfill our social responsibility, pay attention to environmental protection, employee welfare, and commit to the sustainable development of the enterprise.

Sixth, look to the future

We will continue to improve management, innovate business models, and work with partners to create a better future.

Our after-sales service team

Our after-sales service team is focused on providing our customers with an exceptional service experience. Here are five highlights from the team:

Technical expertise: Our engineers are highly skilled, able to respond quickly and solve customers’ technical problems.

Comprehensive maintenance: Provide a full range of repair and maintenance services to ensure the normal operation of equipment.

Customer first: Always put customer satisfaction first, listen to needs, and actively improve.

Efficient resolution: Quickly locate problems and provide efficient solutions to reduce customer wait times.

Continuous improvement: Continuous learning and training to adapt to technological changes and improve service levels.

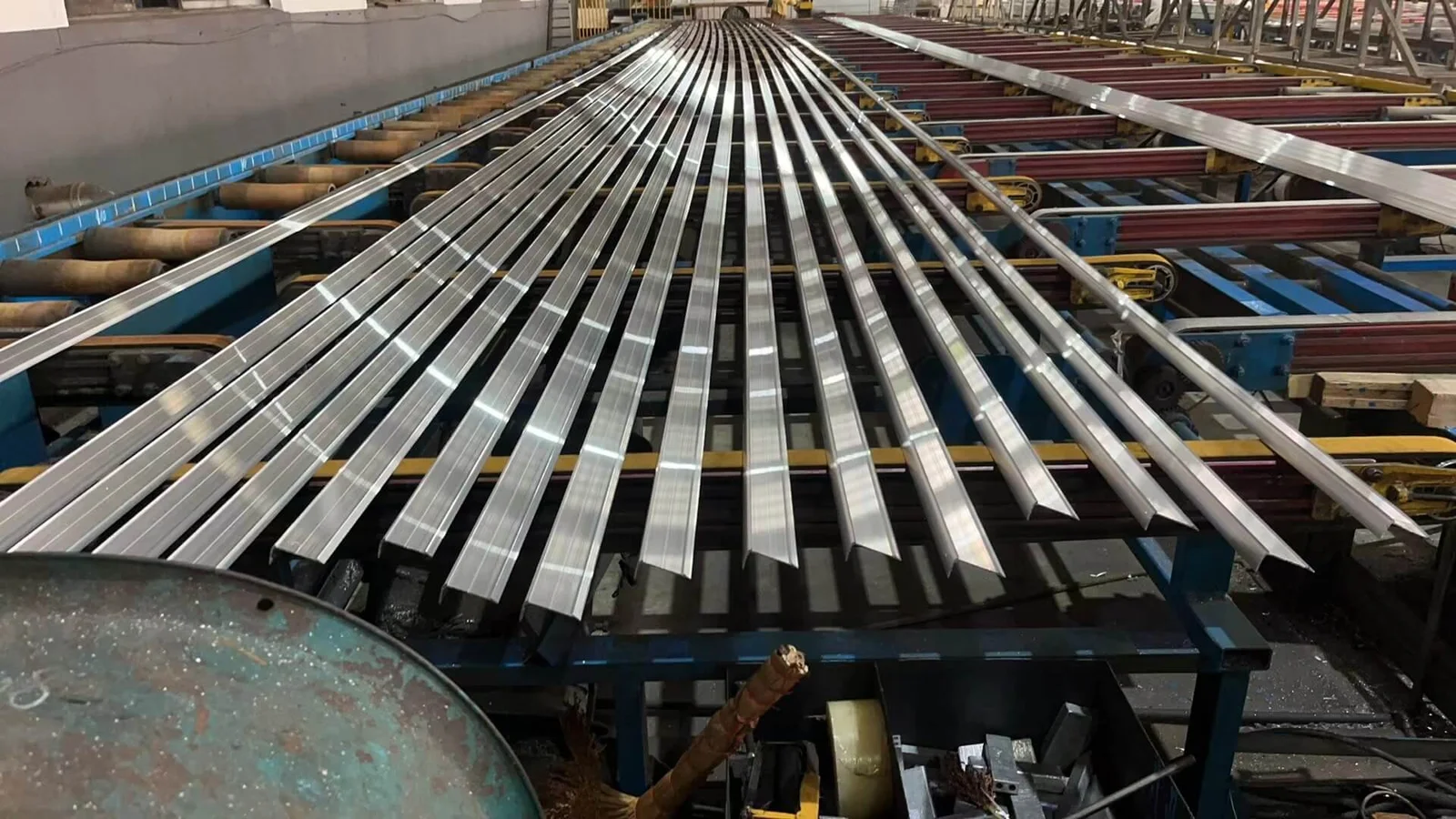

Aluminum Extrusion

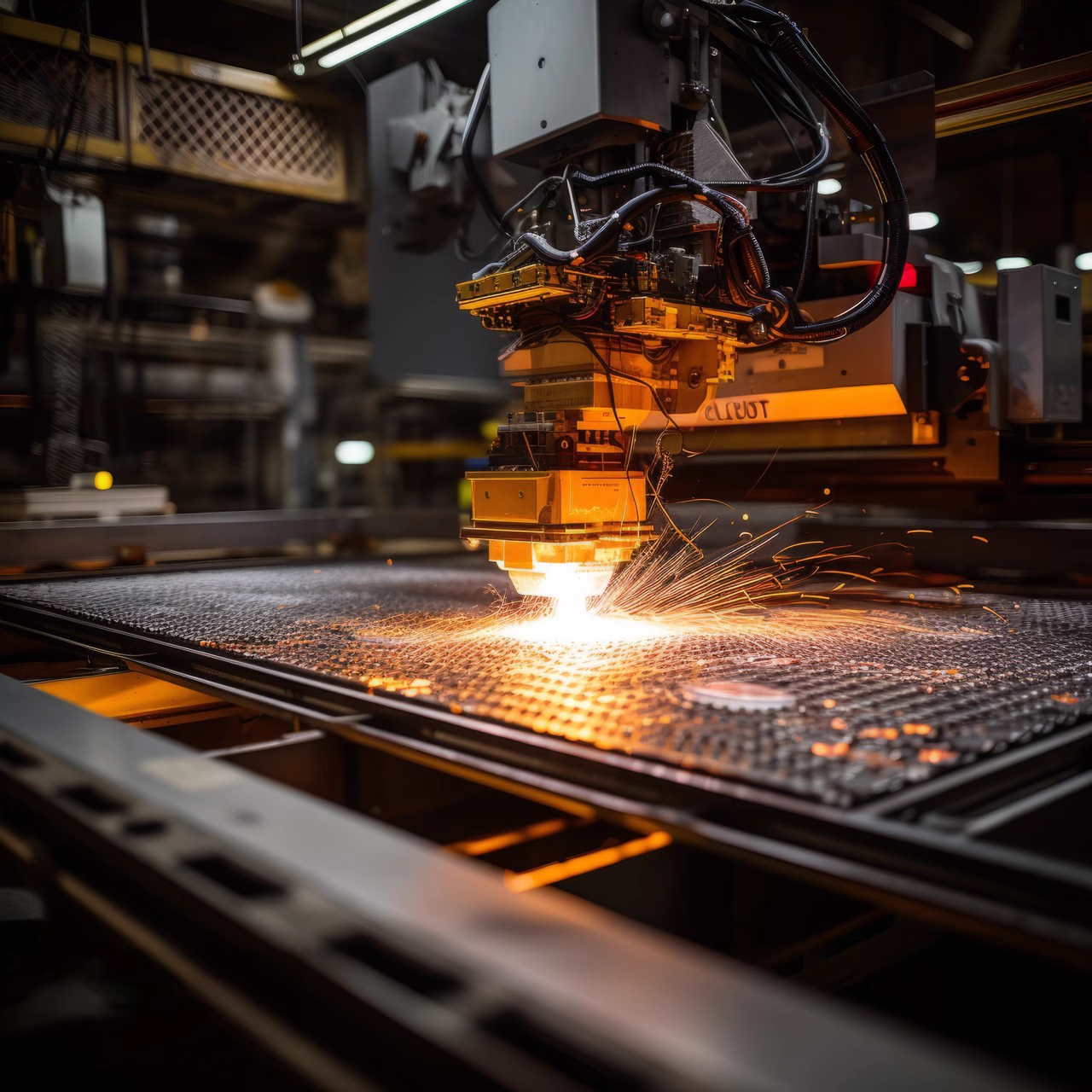

Laser Cutting

Injection Molding

CNC Machine Tool Production

Metal Die Casting